Study of

the radiative properties of rough surfaces for temperature measurements in rapid

thermal processing

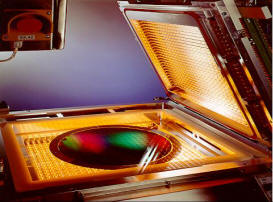

The

motivation of this research is to accurately measure the temperature of silicon

wafers using radiation thermometers during the rapid thermal processing (RTP),

see Fig. 1. RTP is a key technique for the advance of integrated circuits to

meet requirements towards the shrinkage of devices size and increasing packing

density. With advantages in temperature control, short cycle, and process

flexibility, RTP has expanded its application areas such as annealing for

surface damage removal, the growth of thin oxides or nitrides, chemical vapor

deposition, and so on. A challenging problem in the RTP technique is to

accurately measure the temperature of silicon wafers (refer to Fig. 1). Due to

fast response and non-intrusiveness, light-pipe radiation thermometers (LPRTs)

are frequently chosen to monitor the temperature of the wafer during processing.

However, in radiation thermometry, the variation in wafer emissivity and the

stray radiation from background significantly affect the measurement uncertainty

[1]. The monitored surface of silicon wafers

generally possesses roughness created by mechanical cutting and chemical

etching. Surface roughness alters not only the emissivity of silicon wafers but

also the effect of the background radiation by scattering the incident

radiation. In fact, the effective emissivity considering the effect of

background radiation is used in temperature reading with an LPRT instead of the

intrinsic emissivity. Therefore, understanding the directional dependence of

scattering from rough silicon surfaces is essential for radiometric temperature

measurement of silicon wafers during RTP.

|

|

|

|

Figure 1.

A rapid thermal processing furnace and the temperature measurement of a

silicon wafer using the radiation thermometer. |

The bidirectional reflectance and transmittance

distribution functions (BRDF and BTDF) are fundamental radiative

properties that describe the re-distributions of radiative energy

after scattering from rough surfaces. Once the bidirectional

properties are known, the emissivity can be obtained from the

integration of them. However, a true importance of the bidirectional

properties lies in considering the effect of background radiation.

Because the background radiation originates from multiple

reflections between silicon wafer and an RTP chamber, knowledge of

the bidirectional properties enables to model the effective

emissivity [2].

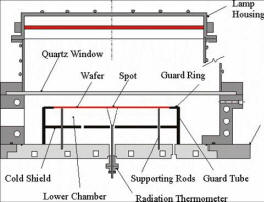

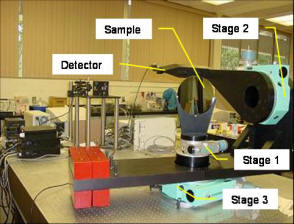

We

started this research by modeling the effective emissivity in an RTP furnace

with the net-radiation method [3] and the Monte Carlo method [4], based on

specular/diffuse reflection assumptions. At the same time, we made an effort to

find appropriate analytical models for the BRDF of silicon wafers using the

reference optical scatterometer at the National Institute of Standards and

Technology (NIST) [5]. Subsequently, we developed a custom-designed optical

reflectometer, namely, three-axis automated scatterometer (TAAS), as shown in

Fig. 2 [6].

|

|

|

Figure 2. Picture and

schematic representation of TAAS. |

The

goniometric table composed of three rotary stages offers high angular resolution

and repeatability to determine the incidence and reflection directions and

allows us to measure both the BRDF and the BTDF in and out of the plane of

incidence with high accuracy. A compact diode laser system provides high

wavelength and power stabilization, and the fiber-coupled laser is easily

interchangeable for a different wavelength. A lock-in amplifier modulates the

power of the laser directly to avoid noises from the background radiation.

Highly linear diode detectors with transimpedance amplifiers provide a large

dynamic range. A reference detector eliminates the unnecessary sample moving and

enables fast sampling. The sample holder allows a large sample up to 8” diameter

to be measured. Heated sample compartment and additional translation and

rotation stages can be included in the system for the emissivity measurement and

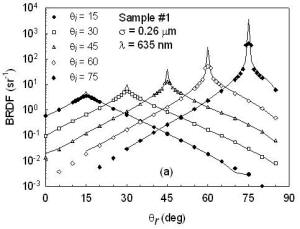

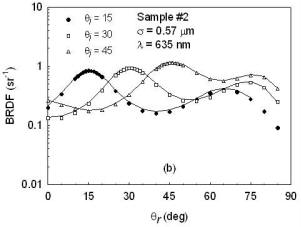

surface scan, respectively. Good agreement was obtained between the measured

results from TAAS and the reference instrument in NIST, as shown in Figure 3 for

two different silicon surfaces. The all-round capability of TAAS allowed

extensive studies of the bidirectional radiative properties.

|

|

|

Figure

3. Comparisons of measurement results from TAAS (solid line) and the

reference instrument in NIST (mark) for two different silicon

wafers. |

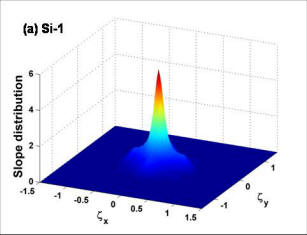

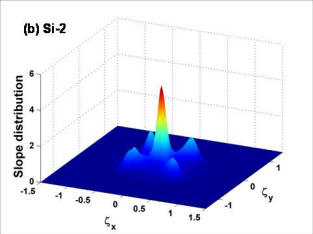

Because the statistics of surface roughness is essential for modeling

approaches, we measured the surface topography of a number of silicon wafers

with an atomic force microscope (AFM). While the height distribution function of

a silicon wafer is close to a Gaussian functional form, the slope distribution

function is anisotropic [7]. Consequently, a one-dimensional modeling approach

with the assumption of isotropic surfaces is not applicable to the BRDF of

silicon wafers. Figure 4 shows the slope distribution functions of two silicon

wafers. Note that Si-1 is slightly anisotropy whereas Si-2 is highly anisotropy

with side peaks. Further study demonstrated that the anisotropic orientation of

silicon surface roughness is caused by the chemical etching process. Using the

geometric optics based model, the BRDF can be correlated with the crystalline

structure of silicon at the microscale [8].

|

|

|

Figure

4. Anisotropic slope distribution of two silicon wafers obtained

from the measured surface topography using an atomic force

microscope. |

Meantime, we have developed a Monte Carlo method to predict the BRDF and BTDF

simultaneously and studied the variation of hemispherical properties under

various conditions [9]. This Monte Carlo method furthermore has a potential to

model the effective emissivity by employing the statistics of surface roughness

such as the root-mean-square (rms) roughness and autocorrelation length, without

relying on the analytical BRDF model. We continued to improve and extend the

Monte Carlo method for the radiative properties of rough surfaces with thin-film

coatings [10] and evaluated the applicability of the geometric optics

approximation with the Monte Carlo method [11]. Recently, the Monte Carlo method

is further developed to directly incorporate the two-dimensional surface

topography obtained from the AFM measurement. The predicted BRDFs of the

anisotropic silicon wafers, based on the measured surface topography, are

presented in Fig. 5, at 30º incidence angle and a wavelength of 635nm. The BRDFs

reveal the same anisotropic features as the slope distribution function shown in

Fig. 4b, implying that the effect of microroughness is significant to the

bidirectional radiative properties.

In future research, we will study thin-film coatings on the

bidirectional properties by coating the silicon surfaces with metallic and

dielectric coatings. The hemispherical radiative properties will be studied with

an integrating sphere, and a monochromatatic light source will be used to expand

the spectral range. In the long run, this research will not only gain a better

understanding of radiation heat transfer at the microscale but also benefit

semiconductor industry.

This work has been supported by the National Science Foundation

(CTS-0236831) and the National Institute of Standards and Technology (Optical

Technology Division).

Selected Publications

[1] Zhang, Z. M., "Surface Temperature Measurement

Using Optical Techniques," in Annual Review of Heat Transfer, vol. 11, C.

L. Tien, Ed. New York: Begell House, 2000, pp. 351-411.

[2] Zhang, Z. M., Fu, C. J., and Zhu, Q. Z., "Optical

and Thermal Radiative Properties of Semiconductors Related to

Micro/Nanotechnology," in Advances in Heat Transfer, vol. 37. New York:

Academic press, 2003, pp. 179-296.

[3] Zhang, Z. M., and Zhou, Y. H., 2001, "An Effective

Emissivity Model for Rapid Thermal Processing Using the Net-Radiation Method,"

International Journal of Thermophysics, 22, pp. 1563-1575.

[4] Zhou, Y. H., Shen, Y. J., Zhang, Z. M., Tsai, B.

K., and DeWitt, D. P., 2002, "A Monte Carlo Model for Predicting the Effective

Emissivity of the Silicon Wafer in Rapid Thermal Processing Furnaces,"

International Journal of Heat and Mass Transfer, 45, pp. 1945-1949.

[5] Shen, Y. J., Zhang, Z. M., Tsai, B. K., and

DeWitt, D. P., 2001, "Bidirectional Reflectance Distribution Function of Rough

Silicon Wafers," International Journal of Thermophysics, 22, pp.

1311-1326.

[6] Shen, Y. J., Zhu, Q. Z., and Zhang, Z. M., 2003,

"A Scatterometer for Measuring the Bidirectional Reflectance and Transmittance

of Semiconductor Wafers with Rough Surfaces," Review of Scientific Instruments,

74, pp. 4885-4892.

[7] Zhu, Q. Z., and Zhang, Z. M., 2004, "Anisotropic

Slope Distribution and Bidirectional Reflectance of a Rough Silicon Surface,"

Journal of Heat Transfer, 126, pp. 985-993.

[8] Zhu, Q. Z., and Zhang, Z. M., 2005, "Correlation

of Angle-Resolved Light Scattering with the Microfacet Orientation of Rough

Silicon Surfaces," Optical Engineering, 44, 073601.

[9] Zhou, Y. H., and Zhang, Z. M., 2003, "Radiative

Properties of Semitransparent Silicon Wafers with Rough Surfaces," Journal of

Heat Transfer, 125, pp. 462-470.

[10] Lee, H. J., Lee, B. J., and Zhang, Z. M., 2005,

"Modeling the Radiative Properties of Semitransparent Wafers with Rough Surfaces

and Thin-Film Coatings," Journal of Quantitative Spectroscopy and Radiative

Transfer, 93, pp. 185-194.

[11] Zhu, Q. Z., Lee, H. J., and Zhang, Z. M., 2005,

"The Validity of Using Thin-Film Optics in Modeling the Bidirectional

Reflectance of Coated Rough Surfaces," Journal of Thermophysics and Heat

Transfer, 19, in press.

Go to TOP